Approved Spring Maker For A Range Of Industries

MARKETS

Hanson Springs is a world leader in spring making, supplying specialist springs to a huge range of industries, including Flow Control, Oil & Gas, Nuclear and Power Generation and Railway industries.

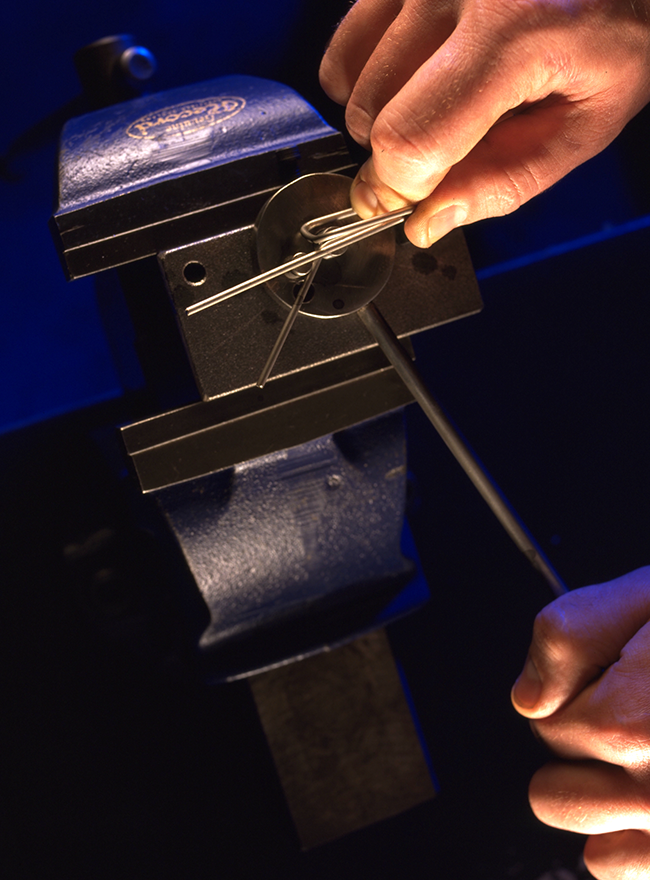

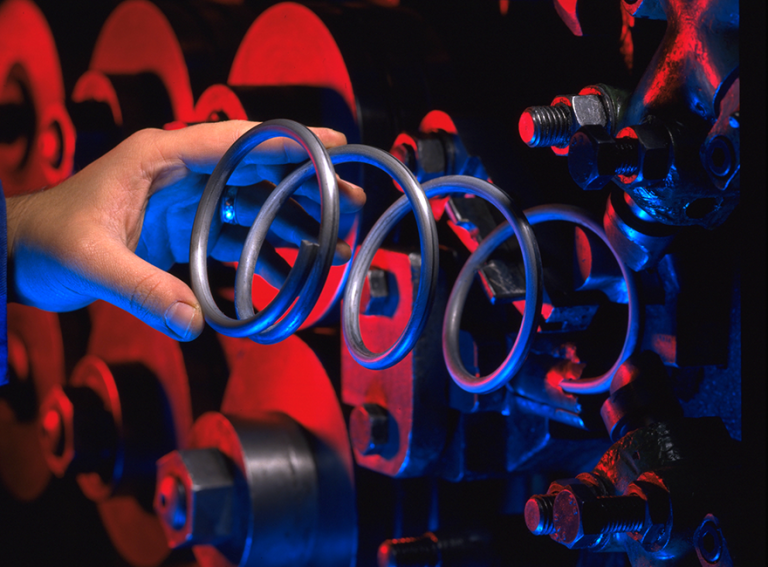

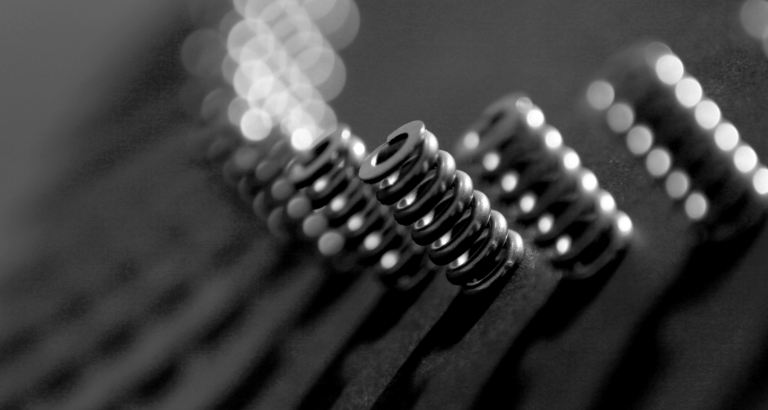

Serving the above markets, we manufacture various compression springs; ball valve springs, check valve springs, actuator springs, crusher springs, screening springs, Antivibration springs, undercarriage springs, bogie springs, piston springs and more… We also hand coil tension & torsion springs, we produce wire forms, and exotic metal Belleville & flat washers; enabling us to fulfil your entire spring assembly requirements and ensure all parts are compatible and SAFE.

We work tirelessly to achieve defect-free, cost effective solutions on time… every time…

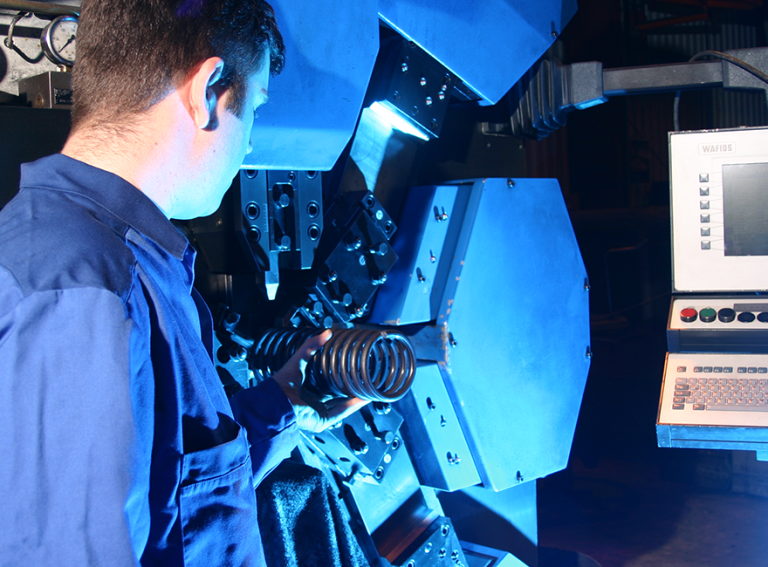

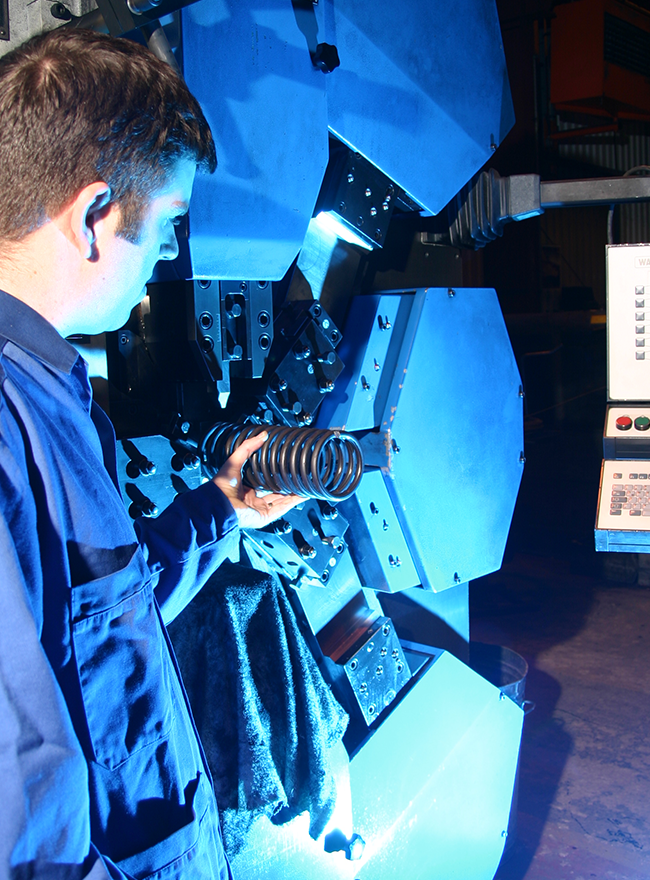

We manufacture springs in Chrome Alloy, Carbon & Stainless Steels, Elgiloy, MP35N, Inconel, Hastelloy and Titanium. Our production methods include CNC Hot-coil & Cold-coil, CNC Auto-coil, Hand Wound Springs & Circlips and CNC Punchpress.

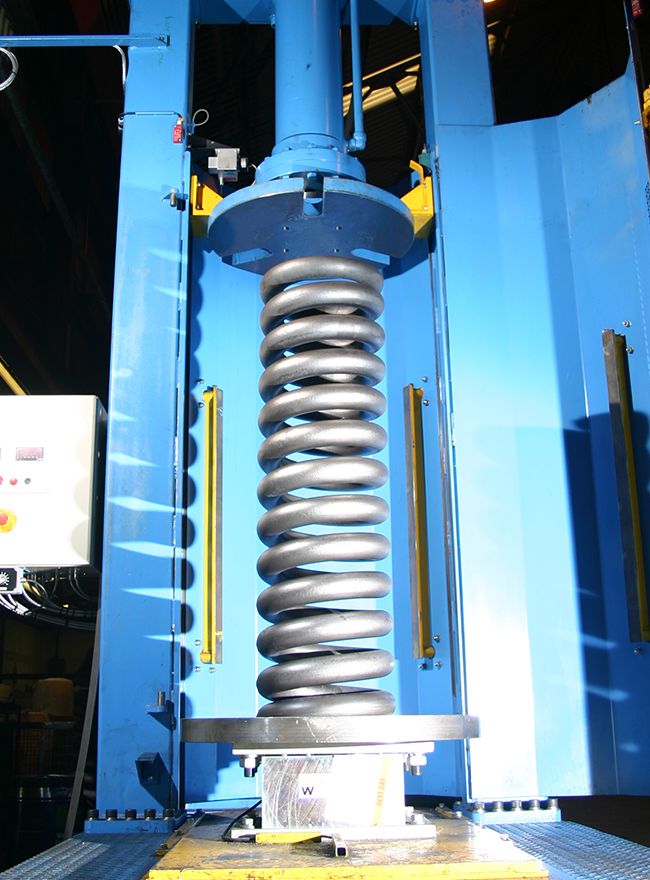

Every stage of the manufacturing process is fully monitored & recorded, ensuring complete traceability. Non-Destructive Testing, Dye Penetrant Testing and Magnetic Particle Inspection (BS6072) are all carried out as part of ongoing quality control.

QUALITY

Hanson Springs stands head and shoulders above our competitors. The attention to detail at every stage – from enquiry, order processing, raw material validation, production and despatch is second to none.

Full traceability of raw material, production and heat treatment records allow Hanson to supply springs for the most demanding applications with complete confidence.

Hanson Springs was one of the first in the spring manufacturing industry to be awarded ISO 9001:2015 accreditation. Throughout our manufacturing plants, quality control is of primary importance, guaranteeing ultimate end product quality and traceability.

Our designers and technicians are always available to advise and assist in solving any spring problem or query, working closely with the Institute of Spring Technology where necessary. Inspection and testing procedures are carried out at every stage in production to ensure the highest possible product quality.

Metallurgical, mechanical and non-destructive tests to A.S.N.T. Level 2 qualification are all undertaken in-house on raw material and finished springs, with certification available on request.

TECHNOLOGY

Rest assured you can order critical components with complete confidence. Coiling and Grinding processes are CNC controlled, all Heat Treatment is electronically monitored and recorded with NDT inspection routinely applied.

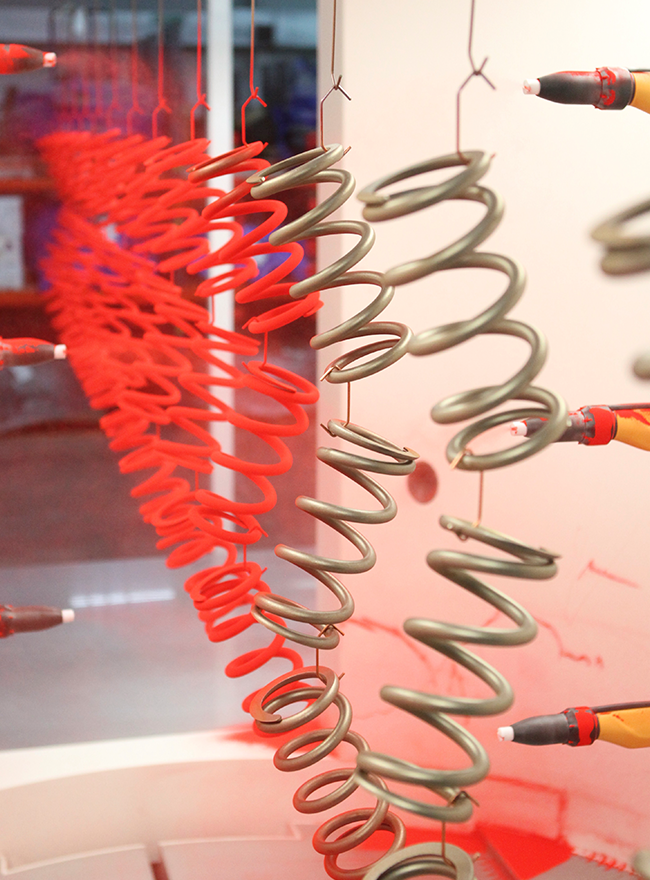

In-house powder coating, plastic coating and aluminising facilities with phosphate prewash allow cost effective use of traditionally corrosion susceptible materials in hostile environments.

Through our policy of continuous improvement and commitment to training, we have developed close links with Rochdale Training Association. All apprentices are given off-site training in their first year, and have both their academic and workshop skills monitored to national standards throughout their 4 year apprenticeship.